The Birth of a Yoyo → Part 1

Introduction

Some kids would sell lemonade in the summer to make a few extra dollars. Others would earn money by doing chores or other tasks around their neighborhood. Me? I used to make yoyos when I was a teenager. I know, it’s not your typical lemonade stand side-hustle, but it was something that I did as a labor of love to a community that had given me so much. Over the last decade, I’ve flown all around the world to attend yoyo contests, was featured on several TV commercials promoting yoyos for Hasbro, and created a small business that sold yoyos worldwide. It was more than just a hobby for me; it was a lifestyle, and it allowed me to flourish into my early teens with confidence and a sense of belonging.

You’ll sometimes see yoyo spelled as “yo-yo”. Either spelling is fine, but I prefer the non-hyphenated one!

I stopped making yoyos a few years ago, just before I attended the University of Illinois, to focus on school and my career as a software developer. It wasn’t until recently that my friend and old business partner reached out and asked if I still had any skin in the game. After recently emerging from a six-year break from yoyo competitions, I found myself increasingly drawn to the idea of reconnecting with the yoyo community. I decided that I should try making yoyos again, and that this time, I would do it a little differently.

I started this series with the intention of documenting the methodology, from start to finish, of making a new yoyo. This post focuses mostly on the process itself, how one would theoretically design a yoyo. My hope is that the next few posts will cover the whole journey of creating a specific yoyo, taking it from a pencil sketch into the real world. I’m excited to share this creative process with you all, but before we begin, let’s talk about the modern age of competitive yoyoing.

Around The World of Yoyoing

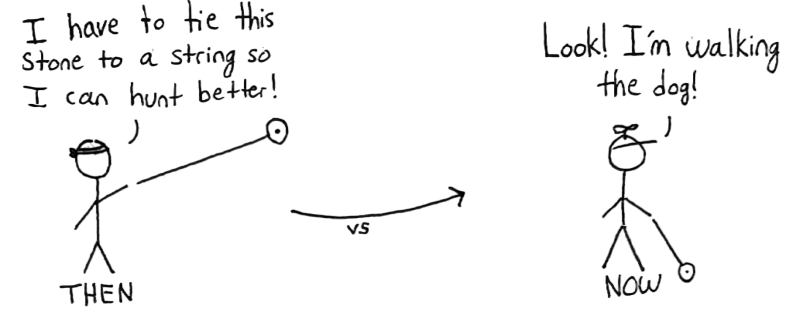

Competitive yoyoing is a rabbit hole of creative expression, raw talent, and impressive displays of artistic performance. Once known as a weapon in ancient Greece, yoyos flourished in the late 20th century, particularly becoming popular in the 1980s and 1990s. The World Yo-Yo Contest, now one of the preeminent competition in the scene, started in 1992 in the United States, and has been a significant platform for the development and evolution of competitive play. The tournament saw players from around the globe showcasing their unique tricks and styles, which expanded the horizons of what could be achieved with a yoyo.

In the 21st century, competitive yoyoing has become a diverse and dynamic sport. There are many different styles of yoyoing, and each has its own unique characteristics and challenges, but all require dexterity, creativity, and countless hours of practice. Competitions now exist worldwide, from regional contests to the annual World Yo-Yo Contest, attracting competitors of all ages and backgrounds. Despite the changes, the core philosophy remains - having fun with a simple toy, while pushing the boundaries of what can be achieved with a piece of string and a spinning object.

Think about the hobbies that you have a strong passion for in your life. What is the origin story behind it? Where did it come from, and how did it evolve into its present day form?

My Journey

I first picked up a yoyo in 2009, shortly after seeing a yoyo show by the amazing John Higby at my local library. Enthralled, I begged my parents for a yoyo, and with the first throw and catch, I fell in love. I must have spent hours honing my skills alone in my room, slowly moving up the trick ladder. My love for yoyoing deepened when I found trick tutorials online, posted by other hobbyists and competitors. YouTube quickly became my personal mentor, with “Yo-Yo Tutorial” my go-to search query.

I also discovered several online yoyoing communities and enthusiastically joined them, forging bonds with fellow yoyo enthusiasts. After a few years of learning the basics, I competed in my first contest on October 16th, 2011: the Massachusetts State Championship. My debut performance placed me 5th in the “intermediate” division and kick-started my journey as a professional yoyoer.

Since then, I have competed in countless events, where each performance is a new artistic expression of my love for the sport. If you’d like an example of what a yoyo contest looks like, here’s me at the 2015 National Yo-Yo Contest, and here is one of my favorite routines of all time.

Hasbro Takes Notice

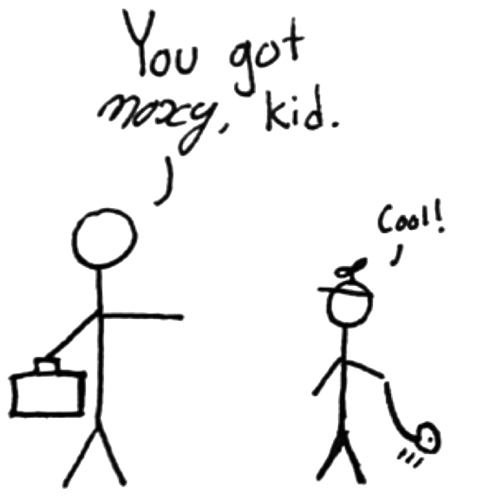

In the mid-2010s, Hasbro, Inc. rolled out a line of beginner-friendly yoyos branded as “Blazing Team” (inspired by a Japanese animated series). In order to promote their new product line, Hasbro talent scouts started attending yoyo contests searching for players who could make their product look impressive. At the age of 14, I was spotted and invited to star in a series of commercials and product demos. This was my first ever job offer, and I readily agreed. I did a few other commercials for Hasbro, and performed at corporate events and Toys-R-Us’s to promote their new yoyos. Between contests and commercials, my online presence is colored with yoyo related content.

A Turning Point

As I continued immersing myself in the yoyo community, I realized there were numerous brands (like Duncan, YoyoFactory, CLYW, OneDrop, among others) manufacturing and selling yoyos. Your affinity to a specific brand became a reflection of your identity, as each brand’s values resonated differently with players. Brands would also sponsor players to showcase new yoyo models during contests and on social media.

However, after several years of competition, I felt that most brands were missing a personal touch. I loved their products, but something was missing. In order to sustain my passion, I knew I had to do something bold: I decided to create my own yoyo company.

I discussed the idea with a few online friends from yoyo forums, curious if they would be interested in creating something fresh. We were young and unsure of the path ahead. But the idea was too exciting to resist. On January 14th, 2014, Tropic Spins Yoyo Company was launched, marking the beginning of an extraordinary journey of entrepreneurship and self-discovery.

The Birth of a Yoyo

Now that we’ve covered my motivation for learning how to create yoyos, let’s dive into the process. To create any product, we need to first understand its design principles. Much like you might question how a piece of fabric becomes a T-shirt, or a piece of wood transforms into a sailboat, how can we mold metal into a yoyo?

A yoyo consists of several parts: two halves, an axle that unites them, a ball bearing that ensures continuous spin, and response pads for a smooth return. The yoyo is used by looping a string around the bearing and attaching it to your middle finger. While we can purchase axles, strings, bearings, and response pads from other sellers, let’s focus on crafting one half of our yoyo.

Modern day yoyos employ ball bearings and silicon response pads to enhance their performance and versatility, factors that are key in competitive yoyoing.

Read More

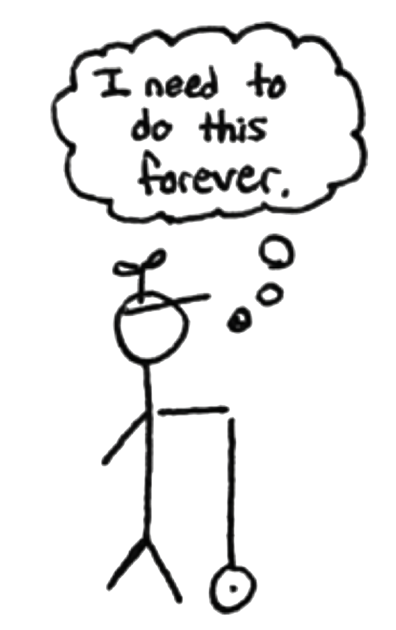

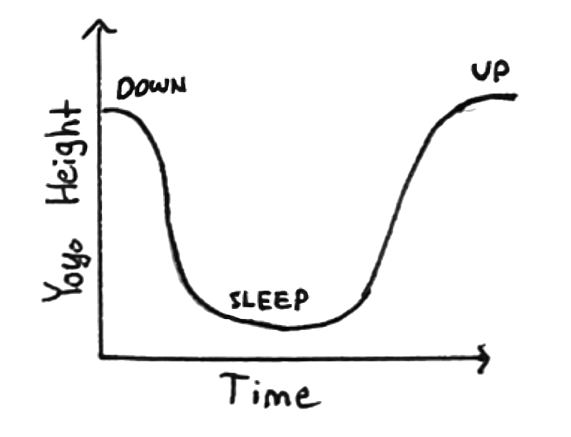

The ball bearing, located at the center of the yoyo, plays a crucial role in the yoyo’s spinning mechanism. As you throw the yoyo, the string winds around the bearing, allowing it to spin freely. This unrestricted spinning ability prolongs the yoyo’s “sleep” time—the period when the yoyo stays at the end of the string spinning without returning to your hand—drastically. This extended sleep time gives players ample opportunity to perform complex tricks and sequences before the yoyo needs to be wound up again.

The silicon response pads, on the other hand, sit on the inner sides of the yoyo halves. When the player tugs the string to bring the yoyo back, the string rubs against these response pads, causing friction. This friction is what triggers the yoyo to “wake up” from its sleep and climb back up the string to the player’s hand. Silicon is typically used for these response pads as it provides just the right amount of friction: not so much that the yoyo is hard to throw or doesn’t sleep well, but enough to ensure the yoyo responds and returns to the hand when desired.

Thus, ball bearings and silicon response pads work together in a modern yoyo to allow for long spin times and reliable returns, making the creative and impressive tricks we see in competitions possible.

Rotational Symmetry, Bagels, and Design

If you’ve ever munched on a bagel while mindlessly flicking a yoyo, you may have missed the uncanny symmetry between these two items. Yes, that’s right. Yoyos and bagels share a peculiar kind of geometric likeness - a mesmerizing rotational symmetry.

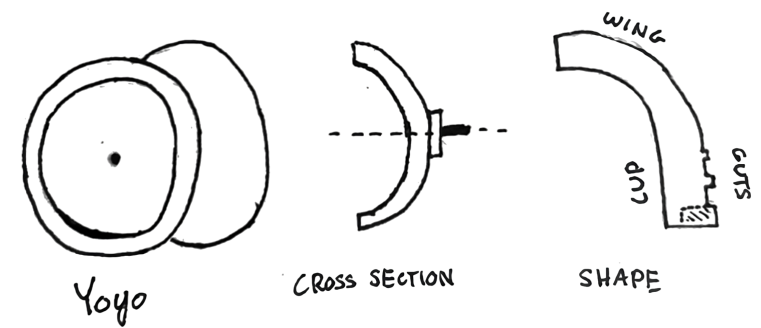

Now, don’t get me wrong. I’m not advocating for slicing your yoyo like a poppy seed bagel. But let’s delve into this weird comparison a little further. Imagine if you could take a culinary knife to your yoyo, the way you would with a bagel. You’d slice it in half once, and then again down the middle. What you’d see is a 2D shape, a cross-section if you will. In the case of our bagel, you would see a perfect circle. For our yoyo, it would be a shape that kind of looks like a wing.

Rotational symmetry, also known as radial symmetry in geometry, is the property a shape has when it looks the same after some rotation by a partial turn. What other objects have rotational symmetry?

Both yoyos and bagels share the characteristic of rotational symmetry - a principle that allows you to imagine them in simpler terms. If you were to cut a cross-section of either a bagel or a yoyo and then spin it around a central axis, you would recreate the original shape of the object. A tantalizing bagel in the bakery display and a spinning yoyo share this fundamental geometric kinship, each with its distinct joy - one for your taste buds and the other for your fingers. Rotational symmetry, it seems, is not just the recipe for a good bagel, but also the blueprint for a well-balanced yoyo.

From 2D to 3D

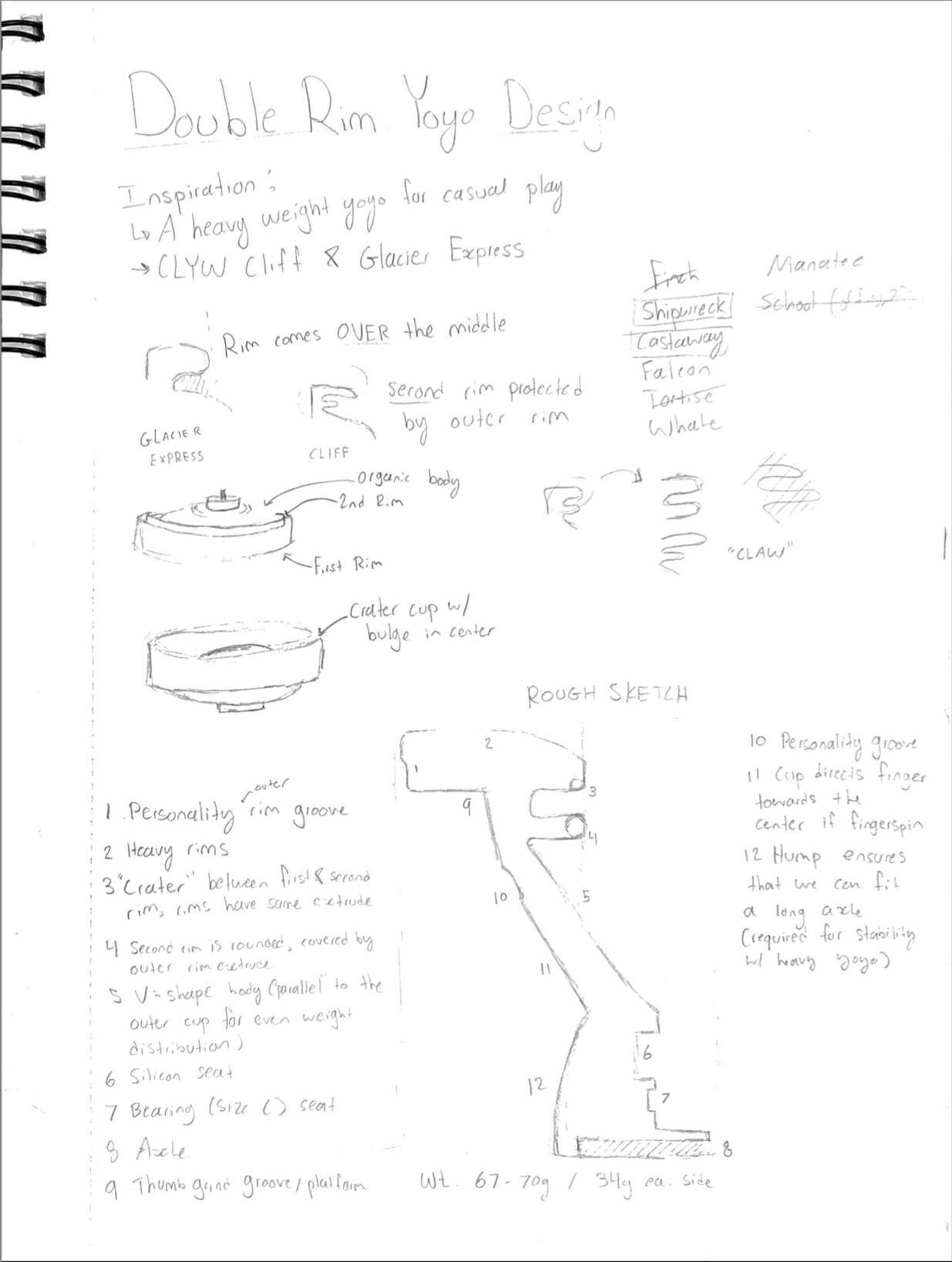

Envisioning the perfect yoyo starts with a simple, yet thoughtful sketch. Like creating an exquisite sculpture, the goal here is to craft an engaging, compelling design. Drawing out the cross-section of a yoyo, that very same design from the bagel comparison, is our first task. We’ll spend time refining this shape, etching curves and lines until we’ve formed a design that catches our eye and fires up our creativity. We don’t need to worry about specific dimensions here, we just need something to reference later. As an example, let’s look at some of my early work, and follow one yoyo’s journey from paper to production.

Sketches for a yoyo with two rims, circa 2015*.

*This is what my sketches traditionally looked like, but I couldn’t find my old design notebooks. The above sketch is a recreation.

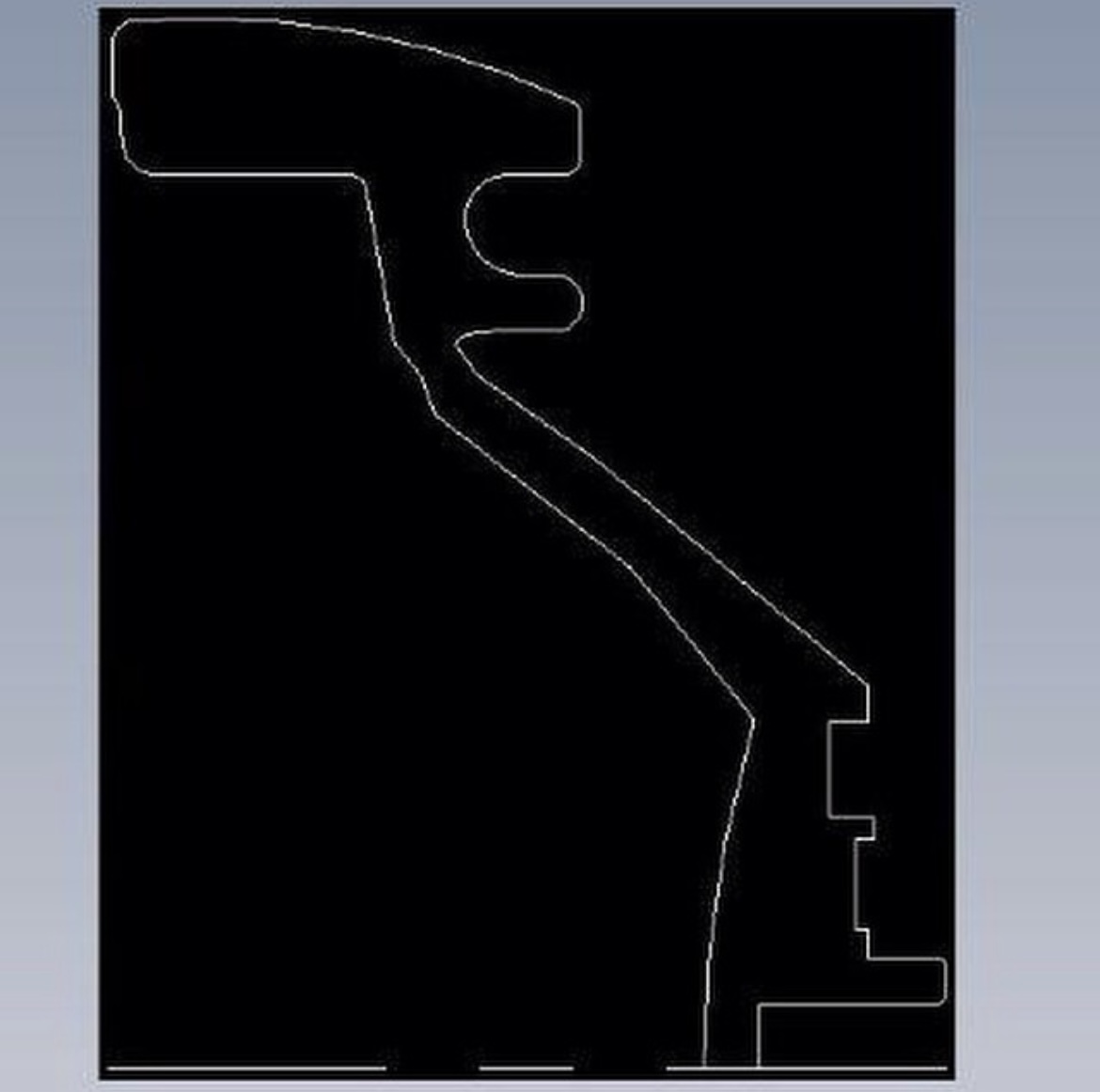

With a shape in mind, we then step into the world of 3D CAD software. I recommend using either SolidWorks or Fusion 360, as they have a relatively small learning curve and are widely used tools in the industry. This is where the magic happens: we draw our yoyo half design in the software with precision, replicating each curve and line from our sketch. The pen-to-paper concept is replaced by clicks and drags in the software, but the heart of the design remains.

The sketch above, drawn in a CAD program, represented as a DXF file (Drawing Exchange Format).

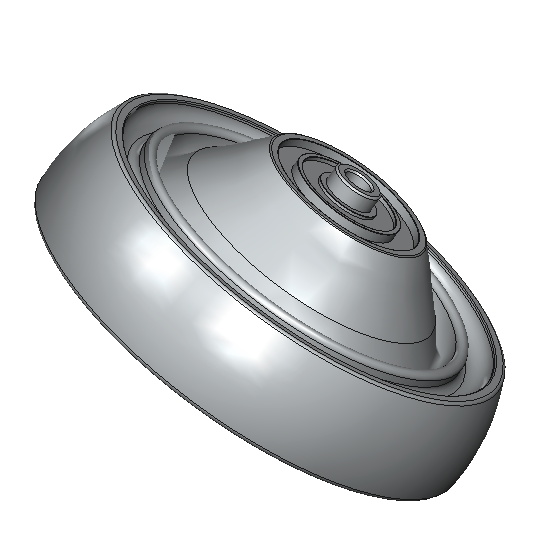

Once we have our sketch drawn out, we can “revolve” it around an axis of symmetry. What we’re left with is a virtual manifestation of one half of our yoyo. It’s here, in this interplay between imagination and technology, that a humble doodle takes a spin towards becoming a real, working product.

A 3D render of one half of our yoyo, later to be named “The Shipwreck”.

How do I find the right dimensions for my yoyo?

Read More

Some general measurements for modern day yoyos include:

- Diameter: The diameter of a yoyo typically falls in the range of about 50 to 60mm (about 2 to 2.4 inches).

- Width: The width is generally a bit less than the diameter, usually ranging from 35mm to 45mm (1.4 to 1.8 inches).

- Bearing Seat: This depends on the type of bearing used, but the most common sizes are “Size A” which has a 5mm (.197 in) inner diameter and “Size C” which has a 1/4 inch (.250 in) inner diameter. The bearing seat’s depth usually ranges from 1 to 3mm.

- Response Pads: The dimensions for silicon response pads are generally about 19mm in outer diameter, 14mm in inner diameter, and around 1.2mm in thickness. However, they can vary based on the design of the yoyo.

- Axle Length: The axle length is usually in the 8-12mm range but can vary greatly depending on the yoyo design. The thickness usually falls into the M4 to M5 metric screw size (around 4 to 5mm).

- Weight: Most modern yoyos fall within the 60-70 gram range (30-33 grams per half, excluding the weight of the other parts).

Although these are the guidelines that I would suggest, yoyos are as varied as the people who use them! Your designs can be small, mid-sized, or bold and hard to ignore. And just like a good pair of gloves, the ideal yoyo size hinges on your hand size, your skill level, and your personal play style.

Putting It All Together

After turning our yoyo design into a 3D file, the first real step in the manufacturing process is to find a professional manufacturer or a 3rd party with a CNC lathe. This advanced machinery is able to mill two perfect halves of a yoyo from a block of material, typically aluminum, according to the precise specifications of the CAD model. There are many manufacturers that have made yoyos in the past who will work with you in order to make sure that your dimensions are correct and that the design in viable.

Once our yoyo has been liberated from the aluminum, the next step is to procure the other essential components - a ball bearing, silicon response pads, an axle, and of course, the yoyo string. These are what make the yoyo spin smoothly, come back to your hand, and overall perform as it should. After the yoyo is assembled fully, the testing phase is crucial to ensure the product’s performance and appeal. It includes checking for ‘vibe’ or uneven spinning, any flaws in the anodization which can affect the yoyo’s aesthetic, and checking for issues like stripped axles which can affect the durability and performance of the yoyo.

The yoyo above, machined using a CNC Lathe and fully assembled.

At this point, we’re pretty much done! The last thing to do, if you’re planning on selling your yoyos, is to distribute them. This could be through a retailer like YoyoExpert, or by selling directly for a greater return on investment. This detailed and arduous workflow explains why a modern aluminum yoyo can range in price from 130 USD. If you’re like me and you just want to make yoyos for fun, a batch of 8-10 prototype yoyos can cost anywhere from 750 USD, depending on your machinist and the materials involved. If you’d like to learn about other types of yoyo manufacturing methods, here’s a great article by Jeffery Pang about using injection machining (the same procedure used to make LEGOs) to create high quality polycarbonate yoyos.

Closing Remarks

The Birth of a Yoyo is a beautiful process, often taking several weeks of planning, coordination, engineering, testing, and distributing. The finished product, however, is a manifestation of hard work and effort. The first time that I ever held a yoyo of my own creation in my hands, I felt like I had unlocked the secret of the universe. I felt like I could do anything!

Today, most of what I create is software, and lives on the web or in the cloud somewhere. While that is magnificent in its own right, I still love to create things that I can feel with my hands. Some of my yoyos have stood the test of time, and others I use as a paperweight or a bedroom decoration. They might not be perfect, but at least they’re mine, even if an imminent solar flare wipes out all electronic records on earth.

So, whether you’re an ardent yoyoer, a dabbler in the craft, or simply a lover of unique, handmade items, I invite you to join me on this journey of creativity, engineering, and nostalgia. The world of yoyos is waiting for you to add your spin, and who knows - your future creation might just be the next big thing.